7 Steps to Build an Effective Sourcing Strategy in Supply Chain

- Date:

- Author: SVI Content Team

- Share:

Souring strategy is essential when you choose to source products for your business in the global trade market. The benefits of having a global sourcing strategy go far beyond what you might expect. In the following parts, we will focus on what a sourcing strategy in supply chain is, explore the advantages and challenges, and, most significantly, show you how to build a strategy that will take your sourcing process to another level. Le’s get started!

Part 1. What Is Involved in Sourcing Strategy?

1) What Is a Sourcing Strategy?

It is the approach that you use to identify and choose suppliers, and evaluate and re-evaluate the sourcing activities in the ongoing process. It outlines how a company plans to procure products to maximize profits and optimize the supply chain with the lowest total cost of ownership and minimal supply chain risk.

2) Components of Sourcing Strategy in Supply Chain

The sourcing strategy involves ways of selecting suppliers, negotiating contracts, and sourcing goods or services. In the meantime, controlling reasonable spending budgets and planning for procurement risks to ensure products arrive on time.

3) Objective of Sourcing Strategy

The essential goal of a supply chain sourcing strategy is to establish longstanding and strategic relationships with competitive suppliers. This is to obtain the optimal quality products within a specific cost while maintaining flexibility to adjust to market changes.

Part 2. Why Do You Need Sourcing Strategies in Supply Chain?

The global supply chain is changeable for businesses to dig for suppliers. A plan for sourcing before the wheel is in motion could direct you to the right path. The advantages of developing a sourcing strategy are:

1) Optimize Costs

By aligning the goal of the plan, it can reduce redundant processes and vet the suitable supplier with efficiency. This helps get competitive product prices, reduce manufacturing costs and achieve better cost control.

2) Manage Product Stocks

Effective sourcing strategies ensure a steady flow of products, helping to maintain optimal stock levels. This reduces the risk of stockouts or overstocking, making better use of resources and minimizing inventory costs and capital.

3) Improve Sourcing Efficiency

A pellucid supplier sourcing strategy streamlines the process by building a standardized process with clear supplier criteria, product requirements and specifications, communication methods and lead times, which boosts overall operational efficiency.

4) Build Sustainable Partnerships with Suppliers

The goal of establishing relations with reliable suppliers in the long term is helpful for a stable supply chain, gaining consistent quality and orders completed on schedule.

5) Minimize Risks for Unpredictable Factors

Well-planned sourcing strategies ensure business continuity and reduce vulnerabilities to supply chain disruptions, such as natural disasters, geopolitical issues, or economic fluctuations, by diversifying suppliers and monitoring external risks.

Part 3. Challenges of Creating a Global Sourcing Strategy

1) Unclear Goals

In the early stages, sourcing strategy goals are often based on experience. However, a lack of experience and info can lead to inaccurate budgeting, poor planning, and ultimately, vague or unclear objectives that hinder progress.

2) Limited Resources in Sourcing Suppliers

Companies, particularly smaller ones, often face resource constraints, including limited budget, or personnel. This makes it harder to dedicate the time and effort needed to search for the most suitable suppliers.

3) Unstandardized Souring Process

An unstandardized procurement process leads to inefficiencies, miscommunication, and errors across departments, resulting in delays and increased costs.

4) Not Implementing Supplier Evaluation

Without ongoing monitoring and evaluation, it’s hard to assess supplier performance, manage risks, or detect potential issues with quality, delivery, or compliance.

5) Lack of Sourcing Expertise

Procurement teams may lack expertise in areas like negotiation, global trade, or supplier management, which can result in poor decisions, excessive spending, or non-compliance.

6) Ineffective Cross-Departmental Collaboration

Misalignment between departments can result in procurement decisions that don’t fully consider other critical factors like budget constraints or technical requirements. This inefficiency leads to information opacity, missed opportunities and increased costs.

7) Poor and Non-Real-Time Communication with Suppliers

Language barriers and delays in communication are the difficulties in global sourcing. It probably gives rise to untimely information sharing regarding changes in demand, or specifications, eventually, affecting order fulfillment.

8) Weak Risk Management

Global sourcing involves plentiful risks that can negatively affect the business. Companies may not identify the hidden risks if you’re not equipped with timely info about variations in your sourcing process.

9) Over-Reliance on a Single Source

Relying on one supplier or region can expose a business to increased vulnerability to supply chain disruptions (e.g., supplier bankruptcy, and supply chain interruptions). Diversifying your supply chain should ease the impact.

10) Difficulty in Lead Time Management

The sourcing process is made of many lead times, such as product development lead time, manufacturing lead time, transportation lead time, etc. The supply chain is susceptible to disruptions. Therefore, it is easy to cause product delays if no measure.

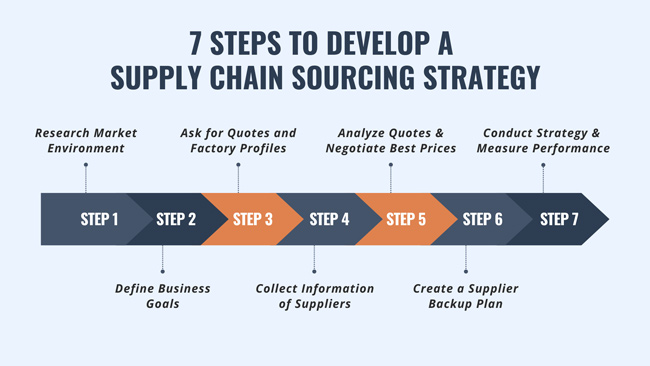

Part 4. How to Develop a Supply Chain Sourcing Strategy?

Learn to build your own sourcing strategy in supply chain management.

Step 1. Research Market Environment

▪ Conduct market research to analyze industry trends, competition, growth rates, and key manufacturing areas where products are concentrated.

▪ Gather data on product costs and analyze pricing trends.

▪ Sort collected information into a document for the record, which is good for future reference to identify potential opportunities and threats.

Step 2. Define Business Goals

▪ Based on research, define clear and measurable goals (e.g., cost reduction, quality improvement, or innovation) that align with your business objectives.

▪ Specify the product items, quantities, delivery time, etc.

▪ Set a budget based on market conditions and company priorities.

▪ Choose optimal regions to source products from by considering the potential U.S. tariffs on imports from China (of up to 60%) and other regions (10% to 200%).

Step 3. Ask for Quotes and Factory Profiles

▪ Provide clear product specifications, quantities, and delivery deadlines, and ask for detailed pricing, terms, and conditions.

Step 4. Collect Information of Suppliers

▪ Request detailed information from potential suppliers and evaluate them, including company type, financial stability, production capacity, quality control systems, product development, delivery times and on-time performance.

▪ Understand suppliers’ cost structure and pricing to gauge whether they offer competitive pricing and meet your budget expectations.

Step 5. Analyze Quotes and Negotiate the Best Prices

▪ Review the received quotes with factory profile, factoring in not just the price of goods, but also the quality control system, lead time, payment terms, production capacity, product development capabilities and business experience in your market.

▪ Choose suppliers that offer the best value for costs by striking a balance between price and quality.

▪ Compare different quotes and negotiate to secure the best deal to identify any opportunities for cost reduction.

Step 6. Create a Supplier Backup Plan

▪ While selecting the best suppliers, identify alternative suppliers who can step in if the primary supplier faces issues such as production delays, quality concerns, or price increases.

▪ Diversify your supplier base can maintain supply continuity and reduce reliance on one source.

▪ Foster healthy competition among suppliers may lead to better pricing and performance.

Step 7. Conduct Strategy and Measure the Performance

▪ Execute your sourcing strategy and continuously monitor its effectiveness.

▪ Establish key performance indicators (KPIs) to measure program effect and supplier performance.

▪ Regularly review the performance against KPIs and provide feedback for improvement.

This ongoing monitoring helps ensure that the sourcing strategy is aligned with business goals, and you can make adjustments as needed to optimize the process over time.

Wrapping Up

Developing a well-defined sourcing strategy offers significant advantages that can transform your supply chain operations. Not only does it streamline the process and enhance efficiency, but it also helps control costs and ensure better supplier relationships. Although creating a successful strategy can encounter challenges, our guide on the 7 steps of sourcing strategy should lead the way.

Want to Find Manufacturers Easily?

If you’re struggling to find the right manufacturers or need expert assistance with sourcing, SVI Global is here to help. As a sourcing company connecting businesses with reliable OEM manufacturers, we place our office across key markets– China, Vietnam, Mexico, etc. Whatever aspect of the supply chain you need assistance with, we’ve got you covered. From sourcing and manufacturing to product development, quality control, and shipping management, our team handles it all. Once we receive your inquiry, we’ll get to work right away to meet your needs.