From Factory to Doorstep: How to Reduce Lead Times in Outsourcing

- Date:

- Author: SVI Content Team

- Share:

Waiting is a part of daily life, we wait for a show to be screened, wait for the time to eat, wait for a bus to arrive, etc. While in the supply chain, waiting is also considered to be one of the processes, such as waiting for the order or project to be promoted, waiting for the product to be manufactured, waiting for the goods to be delivered, etc., which accumulative the lead time that refers to the entire duration of the supply chain process, from the initial order placement to final delivery of the products.

Whether it is in daily life or commodity trading, the longer the waiting time, the more energy and patience are consumed. Therefore, Lead Time Reduction in the supply chain industry has become critical. By minimizing lead times, companies can optimize their operations, improve customer satisfaction and achieve greater efficiency. This upcoming content will focus on the causes of long lead times, emphasizing the importance of lead time reduction and its strategies, so with no further ado, let’s get straight to the point.

Part 1. What Is Lead Time?

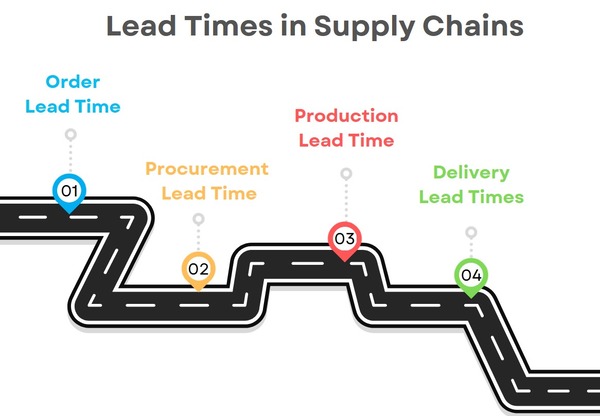

The definition of lead time in the supply chain refers to the total time required to place an order, produce the required product and finalize the shipment without any finished goods or inventory. It contains all activities and processes involved in the development, procurement, manufacturing, and transportation of goods.

The gross lead time varies depending on the goods to be produced, the quantity of the order, etc. For example, producing a complex and high-tech product will have a longer lead time than producing a standard and non-complex product.

But to define a “long” lead time, you will need to consider different factors. According to the average lead time of products in each industry, you can learn whether the supplier exceeds the average duration. Moreover, to evaluate it, you can review your past orders, and analyze the lead time offered by several suppliers while accessing the market and industry trends.

Part 2. What Leads to Long Lead Times in Supply Chain

Check out some possible factors that can cause extended lead times in supply chains.

1. Lack of an Adequate Workplan

A comprehensive work plan can facilitate a smooth process. It includes a clear understanding of the entire process of procurement, the sequence of the process, the specific requirements of the product, the assignment of specific tasks, a potential risk plan, and so on.

The failure of a well-organized schedule can lead to inefficiencies, errors or omissions in work, bringing about not merely delays in lead times, but increased costs, staff allocation and management issues, as well as the difficulty of maintaining customer stability.

2. Bulk Order Taking/Urgent Order Handling

Staff who take large or urgent orders without analyzing the capacity and manpower of the manufacturers, whether it is a mass shipment or an urgent order, will result in an undersupply of productivity, disrupting existing production, putting enormous pressure on raw material and human resources, and leading to unsynchronized production schedules and longer lead time.

3. Inadequate and Untimely Communication

While outsourcing in supply chain management, the existence of time differences and language barriers between a company and its partners is inevitable. Insufficient and untimely communication will lead to delays in order placement, which in turn affects the time of the entire outsourcing process.

Furthermore, insufficient communication will cause the failure of clear specifications of products, quality requirements, lead times, and other details of the outsourcing process, while delayed communication will create a lack of visibility, which makes it impossible to follow up on the project’s progress and solve issues in time.

4. Iterative Product Testing

While product testing ensures the quality and safety of products, it also places pressure on manufacturing time. For example, the manufacturing of electronic products requires passing numerous tests and product certifications from importing countries.

Whether testing samples before or after production, multiple product tests take time both to test the product and to modify any deficiencies, so the testing process will take extra time before formal or mass production. The time taken for product testing should be taken into account.

5. Raw Materials Unavailability

The absence or shortage of raw materials can interrupt or slow down production. Waiting for the arrival of raw materials or seeking new suppliers can make it difficult to meet the required lead time.

6. Specialized Personnel Shortage

If a supplier or factory is understaffed in a process, there will be increased pressure on workers, which can lead to inefficiencies. Neither recruiting more people nor assigning officers to continue with tasks will help to slow down long lead times.

7. Unpredictable Factors

Besides the factors you can foresee, there are unpredictable events that can prolong the lead time. For example, there is exposure to natural disasters, political unrest, worker strikes, new customs regulations, transportation delays, and so on, in the production process. All of these are challenges to the success of cargo importation and exportation.

Part 3. Why You Need Lead Time Reduction in Supply Chain

Short lead times are indicative of a company’s overall work ethic and efficiency, service to customers, order fulfilment, contract obligations, problem-solving ability, etc. That’s why a company needs to adopt Lead Time Reduction which is to minimize the time spent on the process from releasing orders to delivering goods to customers’ doorstep. Following are the benefits of reducing lead time.

1. Boosting Work Efficiency and Enhancing Competitiveness

Long lead times show that some processes are taking an excessive amount of time, so by streamlining processes to reduce lead times, the company’s efficiency and effective communication between workers can be improved.

At the same time, it helps a company to maintain high competitiveness in the sector, because shorter lead times mean that customers are not waiting for a long time, and in a market with a fast pace, the organization that stays highly productive has the edge to excel and to be at the forefront of customers’ choices.

2. Reducing Operational Costs

The longer the lead time, the higher the operational costs. Lead time reduction can minimize the time by optimizing the operational process. Without unnecessary steps, costs of labour, material waste, etc. can be cut down.

Apart from that, since product quality needs to be guaranteed in an appointed time, it demands that workers pay more attention to quality control. The earlier quality problems are detected, the lower the risk of rework and returns, which helps to reduce costs due to quality problems to a minimum.

3. Improving Cash Flow and Agility

By fulfilling orders faster, the company can receive payment from the customer at a fair lick, thereby increasing the cash flow. What’s more, with more time and funds, the company is able to develop business and make strategic investments to drive further business growth and profitability.

4. Speeding up Time-to-Market and Gaining Competitive Edge

Faster lead times enable businesses to bring new products to the market at an early stage, which is advantageous to capture market share and gain a competitive edge. With rapid production, the company can adapt to market trends and receive early feedback from customers to improve products.

5. Enhancing Customer Satisfaction and Loyalty

Customers tend to favour short lead times in supply chains. Even in our daily lives, when we purchase items online, we’re desirous of receiving them as soon as possible, not to mention customers who choose to outsource in the supply chain. Being able to deliver goods from the factory to the customer’s destination on time is something that satisfies them. It brings profitable effects on the company’s reputation and continuing cooperation between clients and the company in the future.

Part 4. How to Reduce Lead Time in Supply Chain

As we discussed in the previous section, prompt lead times can be profitable, and the lead time acts as a yardstick to measure whether there are improvements to the workflow. From lengthy lead times, we can identify problems and address them one by one to shorten the total lead time. How exactly can we do this? Below we will detail a few lead time reduction strategies.

1. Efficient Project Scheduling

Having efficient planning lays a solid foundation for lead time optimization. A well-defined project and production plan effectively manages the timeline of the project, reducing unnecessary delays by determining the sequence of each step; it also includes contingency planning for potential risks, assignment of tasks, ensuring that each task is accounted for and continuously promoted, etc., thus achieving better control and reducing the duration of the project.

2. Streamlining Non-Essential Processes

Usually, issues can be identified and lessons learned at every end of a project, like which processes were too lengthy and whether bottlenecks were encountered. By streamlining non-essential processes, companies are able to simplify the workflow and focus on the important events of the project to optimize the overall efficiency and ensure efficient use of resources.

3. Embracing Automation and Digitization

By automating manual processes, it gives the chance to increase accuracy and as well reducing lead times. With data digitization, it provides up-to-date information for the project, which is convenient while sharing it with workers and clients in no time.

From ordering to shipping the entire process, spending extended time is most likely to be in the communication part, from the beginning of order receiving, to the end of goods delivery. It’s never a mistake to stay in close contact with your suppliers.

Staying in touch with suppliers allows for open and effective communication. This lead time reduction method helps clients to ensure the details of products, find and solve issues quickly, and even have the right to monitor production to enhance the process running with no hassle and receive the final product within lead times.

5. Continuous Personnel Training and Technologies Learning

Personnel training, regardless of professional skills, or soft skills, continuous training can enhance the learning ability of employees, and thus be able to perform the work in an efficient manner; and learning new technologies, such as automation tools, data analysis software and so on, will have an important impact on boosting the productivity of work, and shorten lead times.

6. Proactive Forecasting to Anticipate and Address Challenges

There are lots of unexpected events during the whole supply chain process. By analyzing data and identifying vulnerabilities, organizations can put contingency plans in place to tackle potential bottlenecks. This proactive risk management can minimize the impact of unexpected events and decrease lead times.

7. Choosing Optimal Transportation Modes and Reliable Carriers

The delivery of products can take time. You can choose the most suitable way to ship the cargo to your destination based on your conditions. After deciding which transportation to take, reliable carriers with fewer delays are crucial to ensure your on-time delivery.

To know which is the best way to ship from China to USA, there are 3 common ways: air freight, ocean freight and courier services.

Lead time has been a factor in increasing competitiveness while outsourcing manufacturing in the supply chain as it directly affects the efficiency of the whole process. Short lead times can bring advantages to us in many ways, such as turning clients into regular customers, increasing the productivity and competitiveness of the company, and more. By analyzing the causes of long lead time, several lead time reduction techniques can be adopted to address the issues.

To receive products on schedule while outsourcing, selecting an experienced and reliable partner is one of the important choices. A positive relationship with the outsourcing partner does the organization good as it will ensure the prompt delivery of goods, which plays a vital role in streamlining operations and meeting customer needs effectively.

In supply chains, SVI Global can be your best bet. From product development to shipping arrangement, we have the expertise to help you manage the entire process. Our team emphasizes effective and transparent communication as we understand the importance of timely and accurate information-sharing can ensure smooth coordination. Twenty years of experience gives SVI confidence to address concerns or problems that may arise. We will be sure to deliver the items punctually if you partner with us, any issues during the process can contact us immediately, and we promise to do our utmost to solve the problem because you are our priority.