Outsourcing Manufacturing: Pros & Cons You Should Know

- Date:

- Author: SVI Content Team

- Share:

Overseas manufacturing has become a crucial consideration for companies aiming to optimise operations and enhance efficiency. Outsourcing, the practice of entrusting manufacturing processes to external partners, offers a wide variety of advantages and drawbacks that demand careful evaluation.

This blog delves into the nuanced perspective of outsourcing manufacturing, shedding light on the benefits that range from cost reduction to global market expansion. Yet, amidst the opportunities lie challenges, including issues of quality control, transparency, and the potential for intellectual property risks. As we navigate the complexities of this strategic business choice, we unravel the pros and cons of outsourcing manufacturing. Without further ado, let’s get started!

Part 1. Why Do Companies Outsource Manufacturing

In the unpredictable and competitive environment of the global economy, more and more enterprises are opting for the strategy of production outsourcing. Why do companies choose to outsource manufacturing? What is it?

Outsourcing manufacturing, simply put, is a way for enterprises to outsource their non-core business to external contractors and focus on their core business. The traditional business model of supply, production and sales as a whole is now less favourable because it takes a lot of time to excel in each field. Under increasing global competition, to improve the core competitiveness of enterprises, they need to focus on the development and management of their core business, so they adopt production outsourcing to make up for the shortcomings by utilizing external resources to cut down the operation and production costs.

There are several reasons widely given for the adoption of production outsourcing by firms:

1) Insufficient production capacity

2) Expensive internal production costs

3) Strategic choices

4) Financial risk control

Part 2. What Are the Benefits of Outsourcing Manufacturing

Now that we’ve explored why companies opt for outsourcing. Next, we will discuss the pros it brings to a company’s development.

1. Lower the Costs

The first thing that comes to my mind is the benefits of cutting expenses. Manufacturing outsourcing delegates some of the operations to sourcing agents that are responsible for the process of production, production factories, product inspection, transportation, etc. Compared to the traditional business model, companies are able to reduce their investment in labour and finance. While maintaining sales, the profits increase. The improved return rate of capital operation opens the door to exploring new projects and developing the business.

2. Accelerate Core Business Competencies

With an excellent and specialized outsourcing partner, firms spend less time on finding and evaluating the right factory. The partner will take care of your requirements and select a suitable manufacturer on your behalf. A team is proficient in managing the entire process and ensuring complete the projects on time so that enterprises can concentrate on their core technologies and businesses with high-added value. Outsourcing with experts will increase efficiency and productivity.

3. Get Help from Professional Skills and Expertise

Reaching a skilled capability is one of the benefits of outsourcing manufacturing. Compared to experienced companies, start-ups that intend to manufacture deal with the personnel shortage and lack a seasoned team.

By outsourcing to a third party in supply chains, the operations can access professionals who can handle the challenges from production to shipment. And the expertise fills the void for start-ups, fostering product development without worries. On top of that, sourcing teams familiar with the regulations of law and government help you meet all the needs of the customer.

4. Increase the Flexibility

By outsourcing simple, non-core tasks, companies can allocate their human resources to high-value-added businesses and strategic businesses, and adjust the demand for their products according to the market demand, thus creating a system that can respond flexibly to changes in the market.

5. Reduce the Risk of Recruiting Personnel

For teams or firms engaged in seasonal production that require specialized skills and production, outsourcing manufacturing to China, Malaysia, or other countries is a strategic move. Not only does it bypass the need to recruit new members for temporary projects, effectively lessening the strain on employee flexibility and increasing stability, but it also reduces the risk of labour disputes and increases overall operational resilience.

6. Entry into New Markets

Opening up the Global market is another pro of outsourcing. Outsourcing allows for customization and adaptation of products to meet the specific demands and preferences of local markets. This localization can enhance product relevance and acceptance globally. For a developing enterprise, it facilitates entry into new markets by aligning production with local regulations and preferences. This expansion contributes to the growth of the company’s global footprint.

Part 3. What Are the Disadvantages of Outsourcing Manufacturing

Meanwhile, when peering at the upsides of outsourcing production, it is essential to evaluate its downsides.

1. Quality Control Challenges

Outsourcing means less effective monitoring of overseas manufacturing. As enterprises relinquish direct control, maintaining a thorough understanding of every detail becomes a complex task.

To navigate this, it’s critical to place a heightened emphasis on clearly specifying your requirements when outsourcing. Given the possibilities for uncertain quality issues throughout the process, rigorous quality checks should persist until the product is shipped to your country. What could do is make your quality standards clear, continuously monitor the behaviour of the outsourced agent, or assign a small number of people who are well-versed in the production process to perform quality control of the production process.

2. Lack of Transparency & Accountability

In the absence of transparent performance metrics, it becomes challenging to assess the outsourcing partner’s effectiveness. Poor performance may go unnoticed, leading to suboptimal outcomes and potentially affecting the outsourcing operation’s competitiveness. Moreover, the lack of accountability can hinder problem resolution and erode trust between the outsourcing agent and its partner.

3. Potential for Loss of Intellectual Property

Among the disadvantages of outsourcing manufacturing, this should be solved primarily. When you’re outsourcing production, there is the unavoidable thing that some confidential information will be exposed to the outsourcing company. The risk of protecting intellectual property (IP) exists. Ensure that both sides are on the same page about what info is shared, and sign contracts that impose hefty financial penalties if anyone leaks sensitive information.

4. Communication Difficulties

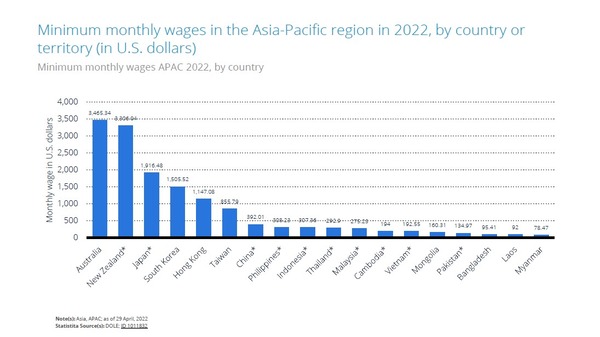

Picking a spot where resources don’t cost an arm and a leg is usually a must for saving bucks. As per recent research, Asian countries are in the limelight for low monthly wages, where are an option to choose manufacturers.

But here’s the hitch–language can be a real buzzkill, and don’t get started on the time zones and cultural gaps. All these things can mess with your project’s schedule. Pulling off a smooth operation requires the staff from both sides to communicate effectively and respect each other.

Part 4. Final Thoughts

Before embarking on the outsourcing journey, it is vital for any company to have a comprehensive understanding of the pros and cons of outsourcing manufacturing. Assessing the benefits and potential risks is necessary to make informed decisions tailored to your business needs. It continues to be a trend to opt for outsourcing, which offers advantages in areas such as cost management and business operations. However, it is imperative to remain vigilant about hidden issues like intellectual property concerns and challenges in quality control, requiring meticulous attention and positive measures.

To address potential issues, fostering a culture of openness, establishing clear communication channels, implementing robust monitoring mechanisms, and incorporating transparency clauses in contracts are essential steps in creating successful and mutually beneficial outsourcing relationships.

If you wonder how to outsource manufacturing, selecting the right sourcing agent holds the utmost importance. SVI Global, backed by a well-experienced team, stands as a reliable partner. It provides ultimate support for sourcing, manufacturing, quality control and product development. With SVI Global, you have a dedicated ally committed to the success of your outsourcing endeavours. CONTACT US and learn more!