The Importance of Quality Control Inspections in Supply Chain Management

- Date:

- Author: SVI Content Team

- Share:

Quality control inspection is a fundamental process that ensures products and services meet certain predetermined standards or specifications. It is crucial in import and export trade because the inspection process is to verify the quality of supplied goods and other relevant aspects of the order and sales contract.

QC inspection, performed by professionals known as Quality Controllers (QC), is a vital component of supply chain management (SCM). By implementing an effective QC system, companies can identify and address quality issues before shipping, reducing the likelihood of customer complaints and returns. This blog will now carefully illustrate the types, importance, benefits and other aspects of quality control in manufacturing for you.

Part 1. What Are Quality Control Services?

Quality control services encompass various activities conducted to ensure that products and services meet predetermined standards and specifications. These services involve inspections carried out by different entities depending on the client’s role in the supply chain.

There are three types of inspection services:

1. First-party inspection: Arranged by the manufacturer themselves.

2. Second-party inspection: Dispatched by the customer company.

3. Third-party inspection: Conducted by external inspection agencies commissioned by the customer.

Effective quality control requires a systematic approach that includes setting quality standards, developing control plans, implementing procedures, and monitoring results. Collaboration and communication among all parties involved in the supply chain, including suppliers, manufacturers, and buyers, are crucial.

SVI Global is a provider of third-party inspection services with a team of over 50 experienced professionals. Our team includes PMC specialists, quality engineers, testing lab technicians, quality controllers, and factory auditors who work systematically to minimize the risk of quality failures from all aspects. Using advanced technologies and industry best practices, SVI Global conducts comprehensive assessments at every stage of production. By identifying and addressing potential quality issues early on, they help minimize costs associated with poor quality products. Our aim is to build long-term partnerships based on trust and quality assurance, providing our clients with detailed reports and recommendations.

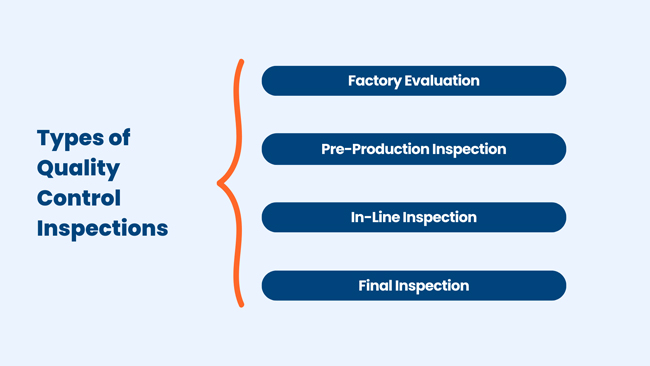

Part 2. Types of Inspections in Quality Control

1. Factory Evaluation – Assessing Manufacturing Facilities

During a factory evaluation, an auditor assigns inspectors to inspect the working conditions, production status, facilities, manufacturing equipment, manufacturing methods, quality assurance management, and personnel of the production enterprise.

This evaluation is conducted according to customer requirements, and the resulting explanations and opinions are shared with the customer. The factory evaluation not only helps customers investigate potential quality accidents but also provides valuable improvement suggestions for the factory.

2. Pre-Production Inspection

Inspection personnel conduct random sampling inspections of raw materials, initial processed products, and components produced during the production process.

3. In-Line Inspection

Inspection personnel conduct inspections of semi-finished products on the production line, checking for discrepancies and deviations, reporting to the factory, and providing effective methods for correcting errors and deviations.

4. Final Inspection

Inspection personnel check the quantity, process, function, color, size specifications, packaging, and other details of the goods before delivery (generally 80% of the products are packaged after 100% of the production is completed). The sample drawn method is carried out in accordance with international standards such as ISO2859/NF X06-022/ANSI/ASQC Z1.4/BS 6001/DIN 40080 and follows the buyer’s AQL sampling level.

Part 3. What Quality Control Methods to Take

Sample Size and Acceptable Quality Level (AQL)

Inspecting 100% of the goods is the safest way to ensure quality, but it can be time-consuming and expensive for large batches. That’s why finding a balance between product quality risks and QC costs is important. This balance point is called the “sample size.”

During the sampling inspection process, QC needs to determine how many defects can be found and what level of defects can be accepted or rejected. This is known as the “acceptable quality level” (AQL).

Types of Defects in Quality Control

During the quality inspection process, defects are classified into three levels based on their severity: critical, major, and minor.

Critical defects are those that can potentially harm the human body or violate laws and regulations, such as sharp edges, corners, and electrical leakage.

Major defects are significant functional or appearance defects, such as poorly printed logos or insulation cups that do not insulate.

Minor defects are minor appearance defects like slight scratches or minor printing defects on the surface.

Experienced QC personnel can usually classify defects based on these principles. However, some customers prefer to create a Defective Classification List (DCL) to ensure that all participating QC personnel understand the defect classification. This list includes all defects related to the product and indicates the assigned defect level for each one.

Part 4. Why Is Quality Control Important in Supply Chain Management

1. Ensuring Compliance

Quality control helps you verify that the goods supplied by the supplier meet the quality requirements specified by national laws, regulations, or relevant standards. This is essential to ensure that the products meet the required safety, health, and environmental standards.

2. Preventing Delays and Defects

Timely detection and prevention of delivery delays and product defects can save you from potential losses and reputation damage. In case of any issues, emergency and remedial measures can be taken immediately to minimize the impact.

3. Reducing Consumer Complaints

Poor quality products can lead to customer complaints, returns, and loss of commercial reputation. By ensuring quality control, you can reduce the risk of such incidents and maintain a positive brand image.

4. Avoiding Compensation and Penalties

Selling inferior products can lead to legal consequences, such as compensation claims and administrative penalties. By implementing quality control, you can reduce the risk of such outcomes and protect themselves from financial losses.

5. Avoiding Contract Disputes

Quality control helps you verify the quality and quantity of goods, which can help avoid disputes over contractual obligations.

6. Selecting the Best Suppliers

By comparing quality control in manufacturing and selecting the best suppliers, you can ensure that they receive the highest quality products and obtain relevant information and advice on product quality.

7. Reducing Costs

Quality control can help reduce manufacturing costs incurred for monitoring and inspecting products. By streamlining the quality control process and reducing the need for rework, you can save time and money.

Part 5. Benefits of Inspection in Quality Control

1. Ensuring Product Quality and Safety

One of the most significant benefits of quality control in manufacturing industry is to guarantee the quality and safety of products.

Quality control inspections can identify defects, non-conformances, and other issues that could potentially compromise product quality and safety. By ensuring both quality and safety, you can prevent defective products from entering the market and gain the trust of customers, leading to repeat business and increased revenue.

2. Maintaining Customer Satisfaction

Maintaining customer satisfaction is a critical goal for those who want to succeed in the long run. By implementing quality control inspections, you can ensure that products meet customer expectations in terms of quality, functionality, and performance. Happy customers lead to positive word-of-mouth advertising and increased sales.

3. Enhancing Brand Reputation and Competitiveness

Quality control inspections can help you maintain your brand reputation and stay competitive.

Consistently delivering high-quality products can differentiate a business from its competitors and help it gain a competitive edge. Moreover, a strong brand reputation can help you attract new customers and retain existing ones.

4. Minimizing Production and Shipping Costs

By ensuring production quality from the very beginning, you can avoid costly rework, scrap, and returns.

Quality check can also help prevent unnecessary delays in the supply chain, which can result in increased shipping costs. Additionally, quality control inspections can help you optimize production processes by identifying areas where they can improve efficiency and reduce waste.

Part 6. Challenges and Best Practices for Implementing Quality Inspections

Most Common Challenges of Quality Control Inspections

1. Resistance to Change

Implementing quality control inspections may require changes to the current production or supply chain process. Employees and factories may resist these changes, causing delays in the implementation process.

2. Lack of Training

Quality control inspections require trained personnel to perform them effectively. However, companies may lack the resources to provide adequate training to their employees.

3. Limited Resources

Smaller companies may lack the resources to implement a comprehensive quality control program, including equipment and personnel.

4. Inconsistent Standards

Inconsistencies in quality control standards across different regions or suppliers may lead to confusion and difficulties in maintaining quality standards.

Best Practices for Overcoming Quality Control Challenges

1. Factory Engagement

Communication is key when it comes to factory engagement. It is crucial to communicate clearly and regularly with the factory to ensure that they understand the purpose and benefits of quality control inspections. It is also essential to listen to their feedback and concerns and address them promptly.

Providing training to the factory staff will also help to build their knowledge and skills, and ensure that they are better equipped to carry out the necessary inspections.

2. Hire a Third-party Inspection Company

Hiring a third-party inspection company can be an effective solution to overcome challenges in implementing quality control inspections. Third-party inspection companies are independent and objective, and they can provide an unbiased evaluation of the product quality and production processes.

At SVI Global, we have a team of experienced inspectors who are familiar with different manufacturing processes and quality standards. Our inspectors are trained to identify any non-compliance issues, and they can ensure that the product and production processes meet the required quality standards and regulations.

3. Utilizing Technology

Utilizing technology, such as automated inspection tools, can reduce the need for manual inspections and increase the efficiency of the inspection process.

4. Standardization of Quality Control Standards

Standardizing quality control standards across different regions or suppliers can reduce confusion and inconsistencies in quality standards.

Conclusion

In today’s global economy, supply chain management has become increasingly complex. With you relying on suppliers from all over the world to provide the raw materials and finished products they need, quality control inspections have become essential.

Quality control inspection is a critical component of supply chain management. It involves examining products and materials during production to ensure they meet required standards. Inspections cover raw materials, components, and finished products to identify defects or issues that could impact quality. By catching problems early, inspections prevent product recalls, customer complaints, and damage to reputation.

Take action today and ensure that your business is implementing quality control inspections in your supply chain management processes.

SVI Global provides quality control inspection services to you in multiple countries. CONTACT US now to learn how we can help you improve the quality and reliability of your supply chain management.