The Ultimate Guide to Ensuring On-Time Deliveries from China's Factories

- Date:

- Author: SVI Content Team

- Share:

China is the global manufacturing powerhouse, producing a vast array of products that reach every corner of the world. For businesses relying on China’s factories, timely deliveries are crucial to maintaining a competitive edge and satisfying customer demands. However, navigating the complexities of production in China can be challenging, making on-time delivery an elusive goal for some companies.

In this guide, we will introduce you to the importance of on-schedule delivery and the key factors that influence delivery times. Also, we will provide corresponding strategies to ensure your products arrive without delays. Let’s take a close look at the vital aspects you need to consider when collaborating with Chinese factories.

Part 1. What Is On-Time Delivery (OTD)?

What does OTD mean? On-Time Delivery (OTD) refers to the timely delivery of products to customers as per the agreed schedule. In supply chain management, OTD signifies the commitment to deliver goods at the right time, ensuring efficient operations and high customer satisfaction.

It stresses the importance of getting products to the right place, at the right time, and in the right quantity.

Part 2. Importance of On Time Delivery

Delivery on time is crucial for ensuring that products reach their destinations as planned. For businesses sourcing products overseas, delays can result in lost sales, dissatisfied customers, and increased costs. Here are some reasons why OTD matters:

1) Meet Sales Demands

For clients who sourcing across the board, a punctual product delivery is a key to maintaining a smooth process. While for retailers, on time delivery ensures the inventory is stocked properly to meet their sales.

2) Reduce Inventory Costs

If the supplier can ship products on time, customers can plan inventory levels more precisely and reduce excessive inventory overhang caused by pr-stocking. Excessive inventory levels will occupy a large amount of capital and increase the inventory management costs (like storage costs, insurance, goods losses, etc.). OTD can help them to reduce these costs and improve the efficiency of capital use.

3) Minimize Logistics Cost

Reducing delays also decreases the likelihood of unexpected costs. Expedited shipping fees or lost revenue from backorders can significantly impact profit margins.

4) Control the Market by Meeting Consumer Expectations

Consistent, on-time delivery not only strengthens reliability but also shapes consumer buying habits. When suppliers deliver products on schedule, it reassures customers that they can count on these products being available when needed. This reliability fosters trust, creating loyal consumers who prefer brands they can consistently depend on. In the long run, this builds market control by aligning with consumers’ expectations and securing lasting business opportunities.

Part 3. What Affects the On-Time Delivery of Chinese Products?

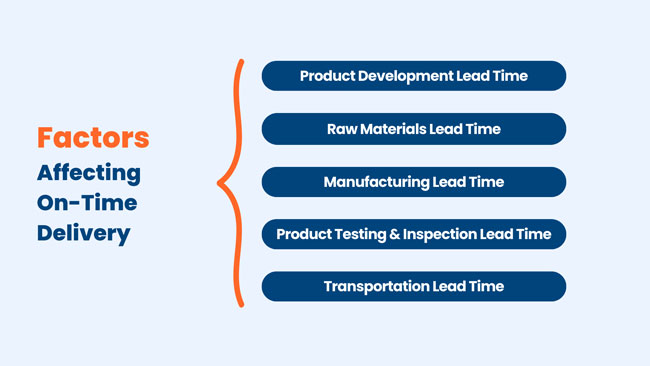

Delivery time is the amount of time it takes for a company to complete the production and delivery of a product or service. Here are elements that constitute the entire process.

- Product Development Lead Time

- Raw Materials Lead Time

- Manufacturing Lead Time

- Product Testing and Inspection Lead Time

- Transportation Lead Time

What Causes Delays in the Delivery of Chinese Products?

Product delivery time is affected by various workflows. To achieve timely delivery, we need to manage the duration of each process effectively, from product development, production, product testing, and inspection, to transportation.

We can analyze the factors that will impact the on-time delivery of products sourced from China from three perspectives.

For Suppliers:

- Full production capacity to put the order first

- Improper production plan or workflow

- Low order volume so the suppliers need to combine several orders to produce

- material unavailability and labor shortages

- quality control issues and failed final inspection

- Lack of technological advancements

- No advanced shipment booking or misestimation of delivery time

For Buyers:

- Urgent order leads to insufficient lead time

- Sudden change in product design or specification during production

- Unclear product quality requirements

- Failure to review production progress regularly

- Local time offset

- Language differences cause misunderstanding

Supply Chain Disruption:

- Extreme weather or natural disasters in areas affecting production schedules

- Port congestion

- Trade policies

- High tariffs

- Geopolitical tensions

Part 4. How to Ensure On-Time Delivery in Manufacturing

To ensure on-time delivery in manufacturing overseas, it is critical to take action to graduate the smooth and successful sourcing process. Here are some strategies that you can apply in your operation.

1) Place an Order in Advance

For suppliers that have limited production capacity or many large orders, the earlier you place an order, the faster the order can be processed.

2) Build Strong Relationships

Establishing a good relationship with your suppliers can lead to better cooperation and prioritization of your orders.

3) Specify Due Time

Communicate your delivery requirements clearly at the outset. Make sure suppliers understand your deadlines and the importance of timely delivery. Avoid unilaterally assigning delivery dates.

4) Communicate Regularly

Stay in touch with your suppliers throughout the production process. Regular check-ins can help identify potential issues before they cause delays. Contact the supplier with a specific goal in mind to confirm.

5) Staying on Track with Order Status

Confirm products to be shipped, check the goods receipt, and make sure that the products arrive on time and in the right quantities. Have your suppliers provide weekly order tracking reports.

6) Plan for Contingencies

Have a backup plan in place. This might include alternative suppliers or expedited shipping options if delays occur.

Conclusion

It is the expectation of every company sourcing from overseas that goods will arrive promptly, as this is essential for fulfilling orders, reducing costs, and fostering long-term cooperation. Nevertheless, the sourcing process is influenced by multiple factors, making it challenging to maintain efficiency when dealing with Chinese factories.

This guide highlights the key elements impacting product delivery from the perspectives of suppliers, buyers, and force majeure events. It also offers actionable measures to mitigate or avoid these challenges. With this knowledge, you can implement effective strategies to achieve your goals.

SVI Global, as a supply chain management company, understands the challenges of global sourcing. Our production management expertise equips us to effectively navigate these complexities. The merchandiser team will consistently monitor your orders and collaborate with various departments to facilitate the sourcing process. You keep abreast of the latest changes and trends that could impact your supply chain. By booking the shipment early, your cargo will arrive at its destination right on time.